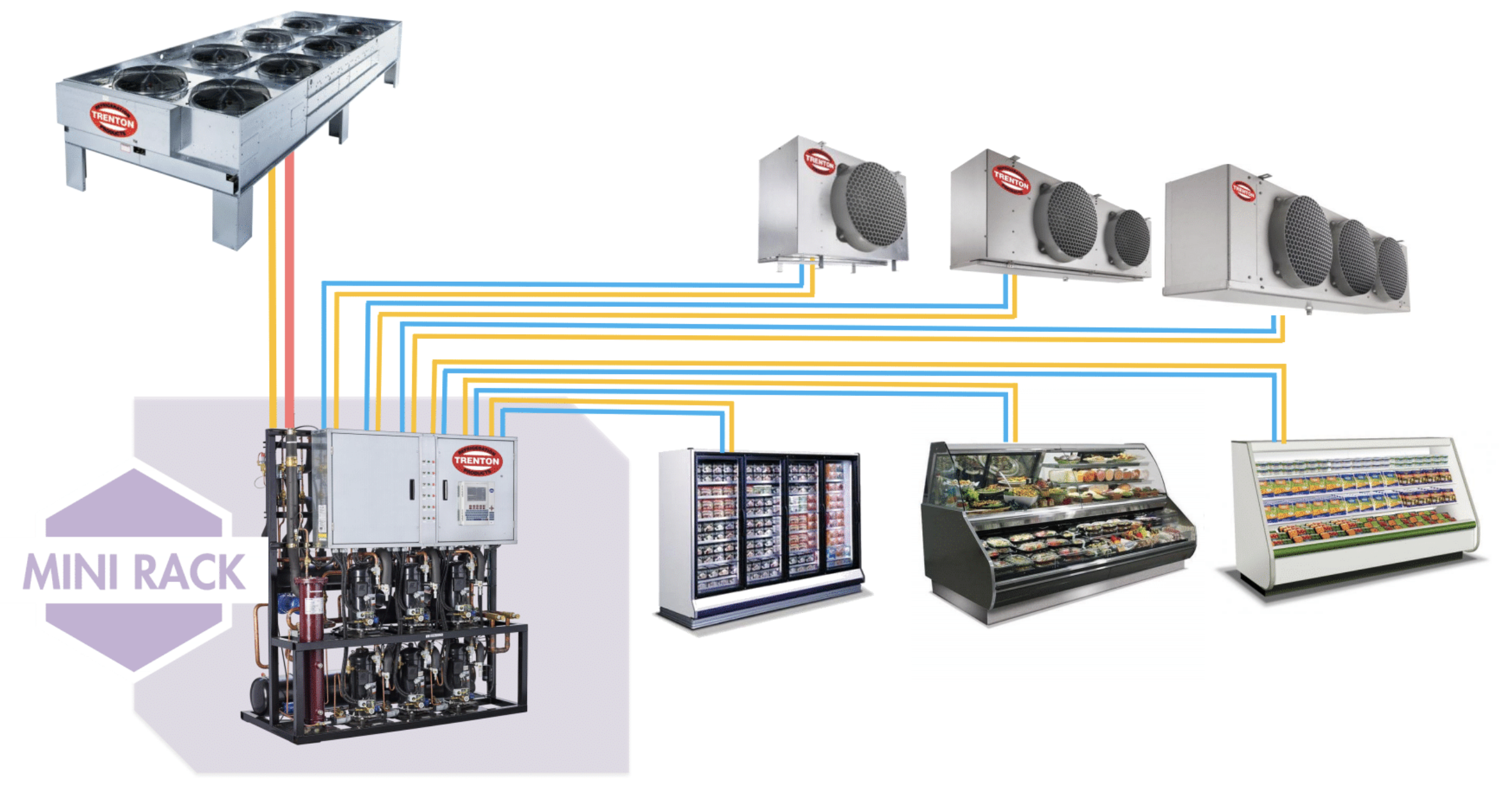

Mini Racks

A Mini-Rack is an indoor Parallel Compressor System with a larger profile than the LINK to be able to house a receiver, branch circuits and other piping/electrical instruments.

The simplistic design of the Mini-Rack allows for 360-degree full access to all of the components making the Mini-Rack easy to service and maintain. The standard Mini-Rack is only 83” height which allows it to fit through man doors.

Application

Mini Rack units are Ideal for larger warehouses as this unit has a larger profile than the LINK, allowing it to house a receiver branch circuits and additional components. The standard Mini-Rack can house a maximum of 8 scroll compressors (17HP each) but it can be customized to fit a specific number of 15HP scroll compressors. The Mini-Rack supports horizontal receivers up to 96” long and all sizes of oil separators. It can fit a number of branch circuits and the electrical panels are spacious enough to house all the electrical components for the compressors, branch circuits and control boards. The Mini Rack simplified design provides 360 degree access to all its components for easier service. This unit can house up to 10 scroll compressors and accommodate a number of branch circuits and multiple electrical panels.

Features

- Lightweight welded and painted structural frame

- Up to 10 (17HP) scroll compressors

- Motor starters providing protection against overload and phase failures

- High efficiency IEC Contactors for compressor control

- Master phase monitor to shut down compressors in case of a phase loss

- Crankcase heater per compressor

- Operating lights and toggle switches for compressors

- Suction headers oversized to function as accumulators

- Catch-All suction filter per suction group

- Discharge thermostats per compressor

- Low and high pressure safeties per compressor

- Electronic oil management system per compressor

- Coalescent oil separator for high efficiency oil separation

- Discharge check valve to prevent back flow of gas from the condenser

- All suction pipes insulated at factory

- Charged with helium and leak checked

- Vacuumed below 500 microns and holding for 24hrs

- Shipped with holding pressure of nitrogen

- Vibration pads prevent transfer of vibration (shipped loose)

- All components UL certified

Options

- Customized structural steel frames

- Horizontal or vertical receiver

- Branch circuits (air, electric and hot gas defrost)

- Mechanical subcooling

- Heat reclaim

- Mounted leak detector for all refrigerant types

- Cross over CPR/check valve for load capacity control between suction groups

- CPC, Micro Thermo, Danfoss and other controllers

- Control boards for evaporator monitoring and control

- Run proofs for compressor and evaporator fans

- Mounted disconnect switch

- Remote defrost panel

- Operating lights and toggle switches for circuits

- Mounted 3-way valve, head pressure regulating valves, flooding valves and other piping instruments

CAPABILITY/COMPATIBILITY